Not only can AI-driven drone data management pinpoint faults down to an individual panel level, solar farm owners can also use this technology to identify trends in array performance and ramp up pre-emptive maintenance efforts.

More and more solar farm managers have begun to use thermal aerial imaging to assess and track the performance of PV arrays at large solar parks.

Traditional aerial thermal imaging techniques zero down on an array which is running at a relatively higher temperature to indicate the possibility of a faulty or declining panel.

But this model does not provide solar farm owners with the complete picture. They still need to identify the individual panels in the PV array that are faulty or under-performing.

And they still do not have any means to receive an early indication of PV panel degradation which would allow them to implement predictive maintenance programs effectively.

Aerodyne Australia is closing the gaps found in conventional aerial inspections by offering a full-service analysis and assessment model driven by machine learning and artificial intelligence (AI).

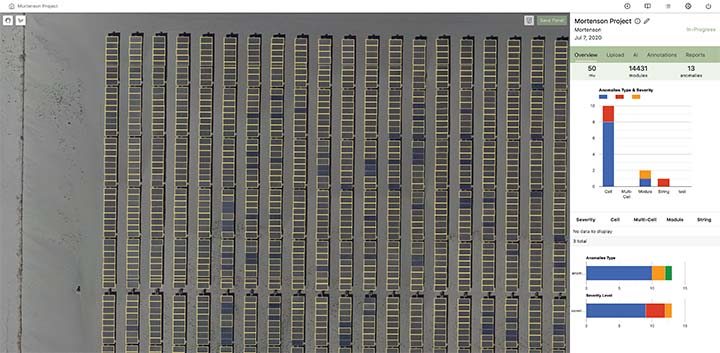

Aerodyne’s cloud-based delivery platform vertikalitiSOLAR rapidly compares imagery from multiple thermal mapping missions to assess and identify trends in PV panel and array performance, delivering exceptional reporting on just those panels where potential issues are being detected.

Every PV array (or even each panel) can be managed within the vertikalitiSOLAR platform as an asset.

For each asset, solar farm owners can assign a precise GIS location and upload useful maintenance documentation, such as historical inspection data and images, installation reports, maintenance reports and engineering and design data.

This allows farm owners to create a ‘virtual twin’ for each array or panel, enabling unprecedented levels of desktop maintenance assessment.

“There’s no mystery about why aerial inspection of solar arrays has become so popular,” Aerodyne Group COO, Rossi Jaafar, said.

“Traditional methods of panel and array inspections are very time-consuming and expensive to sustain in a market where financial returns are still relatively low.”

Aerial PV array inspections can deliver critical information much faster and usually much more cheaply. But the challenge is that they produce a huge amount of data and imagery, which then has to be collated and analysed before it can be readily consumed for maintenance purposes.

“The real game-changer,” according to Rossi, “is being able to capture high-resolution visual and thermal imaging, that provides panel-level detail, and delivering this data in a way that client management and maintenance personnel can use readily and easily.”

With an in-house thermographer on its analysis team, Aerodyne Australia can identify, classify and detect each anomaly clearly and consistently, as well as make assessments on the performance of the system.

Once the data has been analysed and processed by Aerodyne’s experts, clients receive a clear and complete health report of the site via PDF, online maps, and field repair mobile app.

They can then plan their next action for repair and maintenance.

This partner content was brought to you by Aerodyne. For more information, click here.